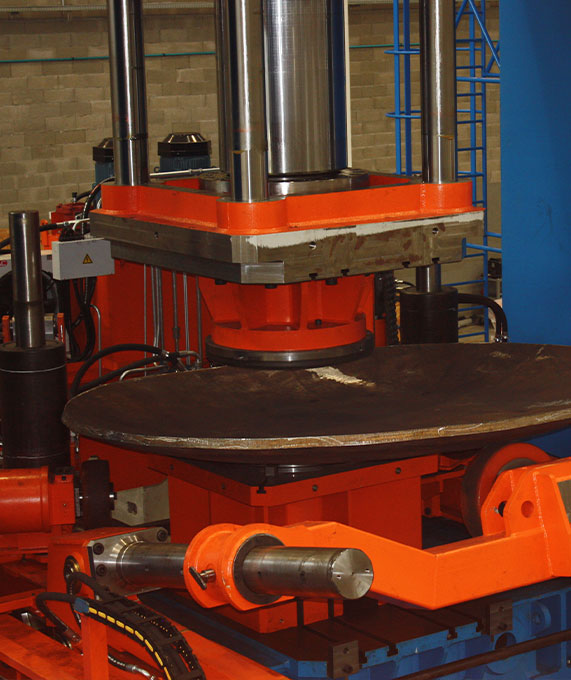

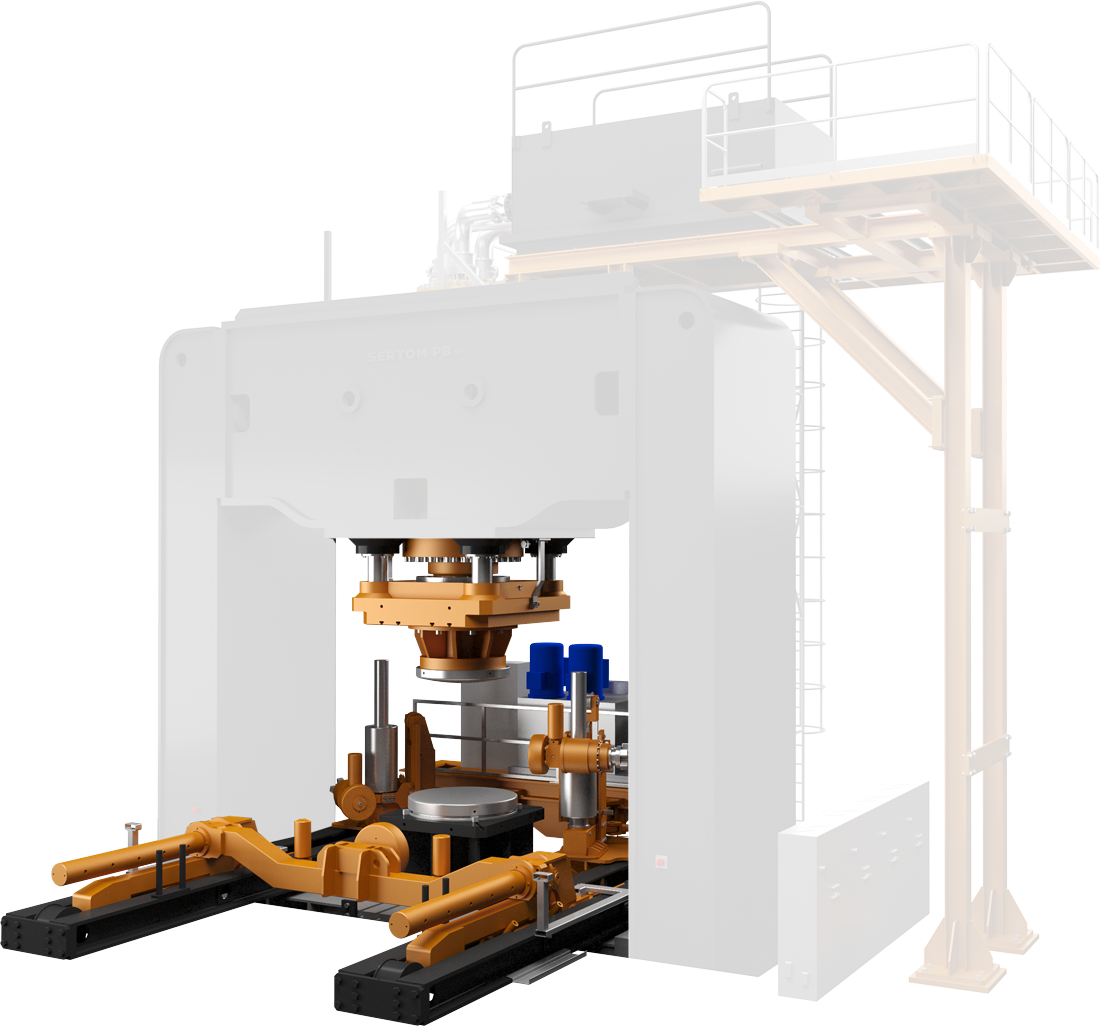

Manipulator

MPI

Sertom P.B. flanging and dishing line

A hydraulic machine for translation and rotation movements. The manipulator is an auxiliary machine that interfaces with the press for the construction of dished heads. The manipulator is synchronized with the press cylinder. Starting from metal discs, simultaneous or single movements and their logical sequence determine the cycles for the construction of the dished heads.

Advantages

Advantages

Standard equipment

- Support arm movement both synchronized and independent

- 2 motorized rollers for disc rotation

- Pre-set counter for the rotation angle

- Pre-set counter for the number of presses in different positions

- Electronic control system

- Siemens or Allen & Bradley electrical components or equivalent

- Hydraulic unit consisting of a group of motor pumps, solenoid valves, by-pass valve for maximum pressure to guarantee overload protection

- All controls are located on an independent control console

- Low voltage controls on the mobile panel, 24VDC

- Safety unit for the immediate stop of all machine movements, which consists of emergency lock buttons and a safety perimeter wire

- Electric motors to power the hydraulic pumps

- Machines built according to the “CE or CSA or UL” certification rules

- Drawings of the foundations and instructions and list of all the equipment necessary for installation

- Instruction manual in the language of the country of destination, complete with hydraulic and electrical diagrams, drawings of the foundations and all the equipment necessary for the installation of the machine

Equipment

Application sectors

Sectors

Gallery

WE HAVE THE SOLUTION RIGHT FOR YOU