Wind Tower

The highest quality and productivity for the wind industry

The Sertom PB machines are the ideal solution for the construction of foundations for wind towers, for the construction of the single poles that support the rotor, in thick resistance sheets. The producers of the sector require, in fact, machines capable of bending sheets. of great thickness and high hardness, ensuring the maximum resistance of the structures made. According to the needs and the required capacities, Sertom PB can supply Plate rolls Machines with 3 or 4 rolls able to bend sheets with a thickness greater than 300 mm, guaranteeing the highest standards terms of quality and productivity.

The fastest machine on the market

Plate rolls Machines designed by Sertom P.B. have an upper roll that rotates at a guaranteed and measurable speed of up to 12 m / min. To cope with the heaviest loads, the gearboxes are two larger sizes than a generic machine. Some of our plate rolls machines for wind towers work 24 hours, from Monday to Saturday.

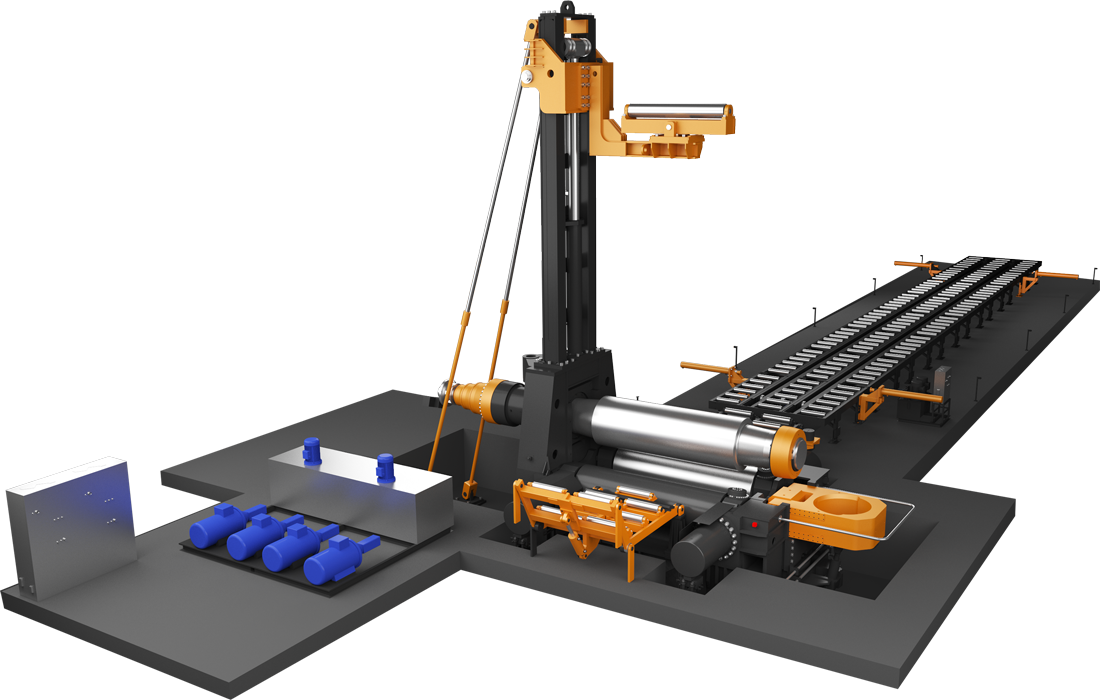

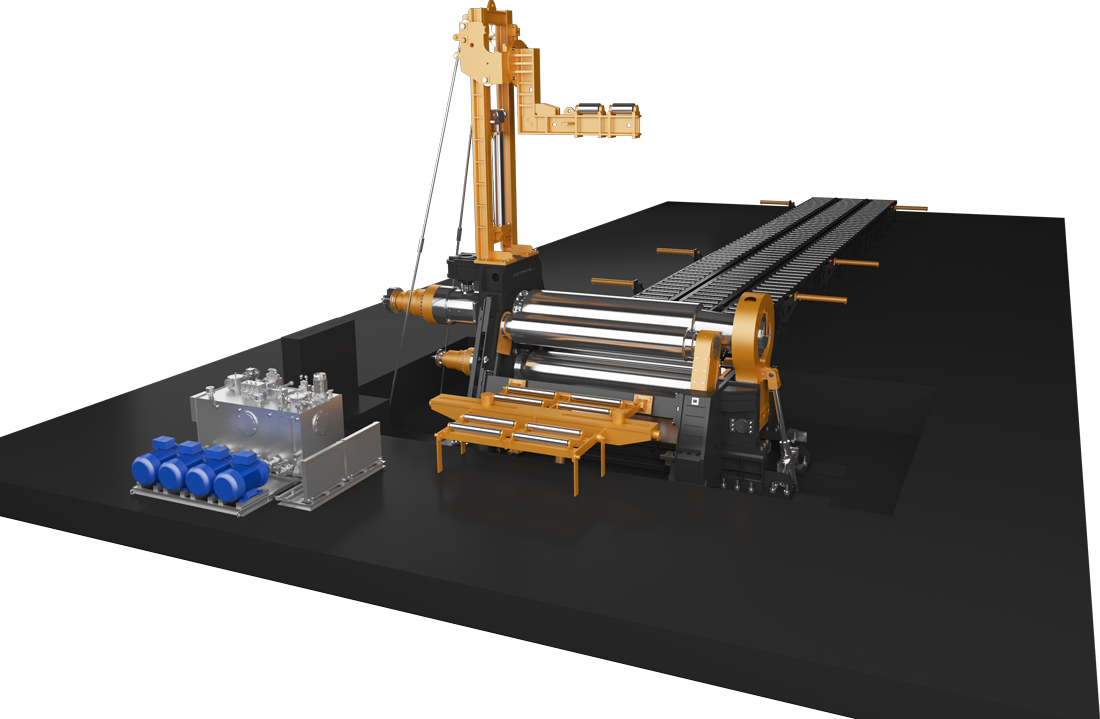

The configuration that we recommend to our customers consists of:

- A roller conveyor for the sheets to feed the machine before bending. It is both liftable and can be fixed to the ground. Both roller conveyors have as a standard feature the device for aligning and centering the sheet before its positioning inside the machine.

- For the side arms supporting the bended sheet, we recommend a double articulated arm and the second double articulated arm with centering devices, necessary to align the two edges of the Plate rolled before welding.

- A top support to support the sheet during the rolling operation.

With the right sizing of the plate rolls it is possible to make a plate rolled every 15/20 minutes. All our Plate rolls Machines are equipped with shock absorbers positioned on the cylinders, so as to make the plate calibration phase less burdensome after welding. This process causes an overpressure which, if not adequately balanced by the shock absorber, can damage the machine.