Corrugate sheet Plate Bending Machine

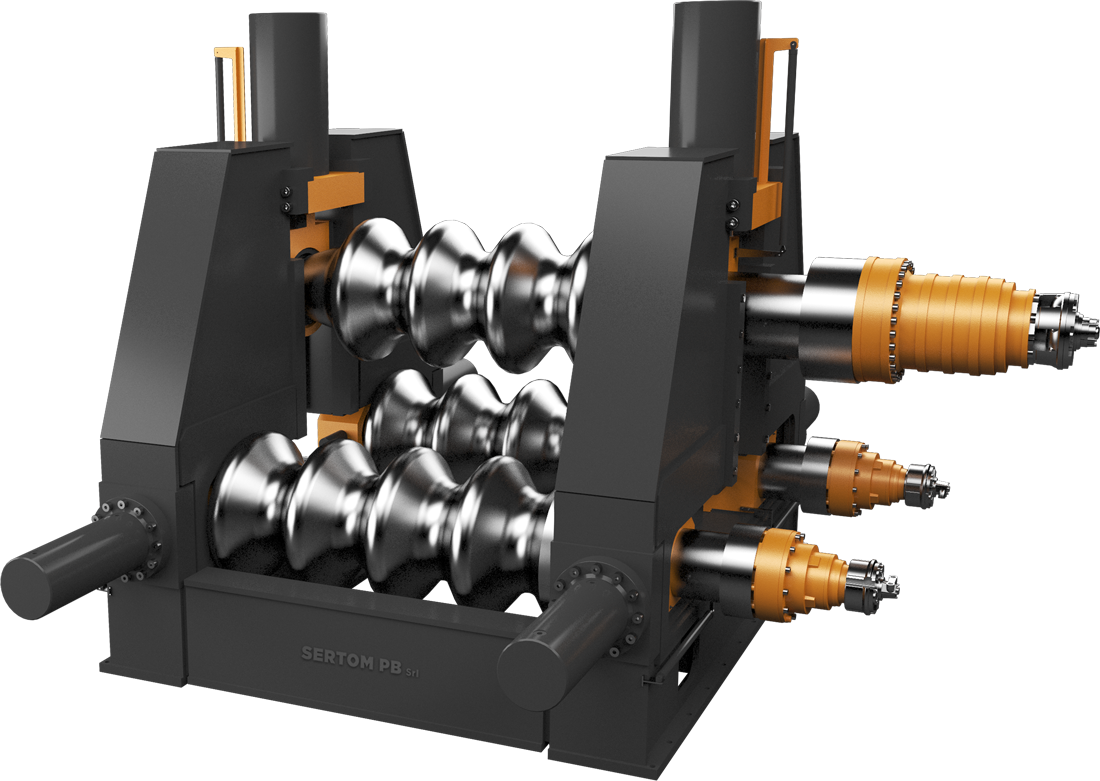

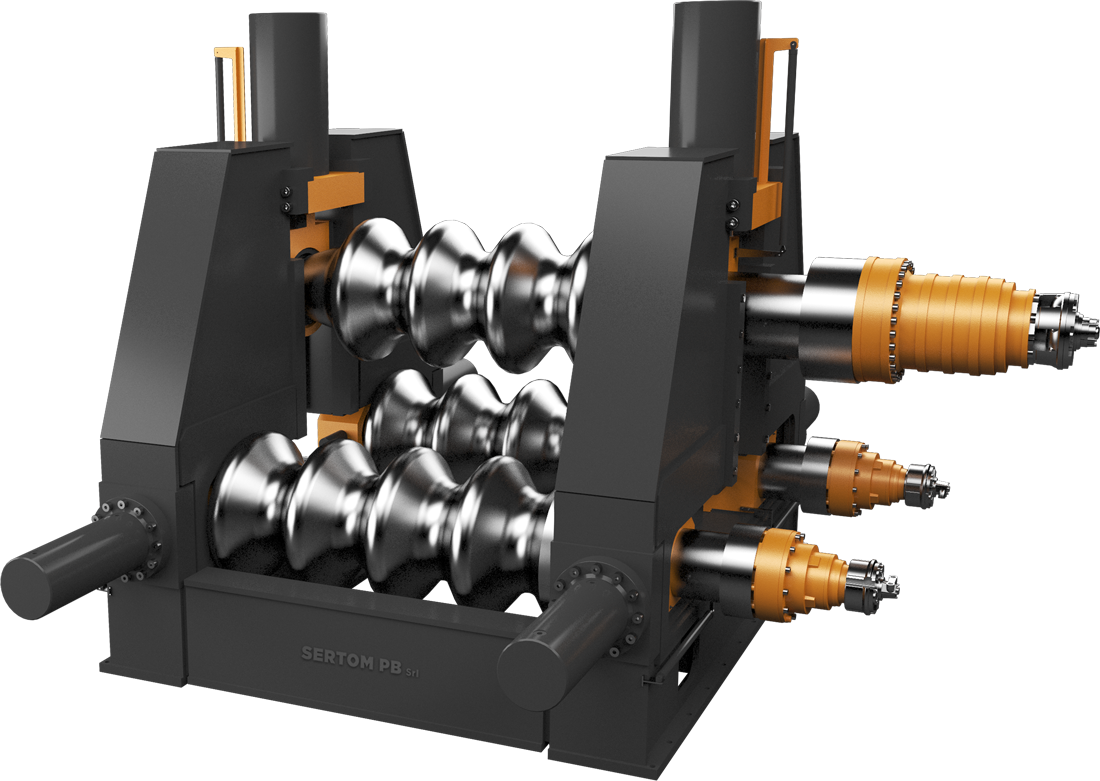

A Special Plate Bending Machine.

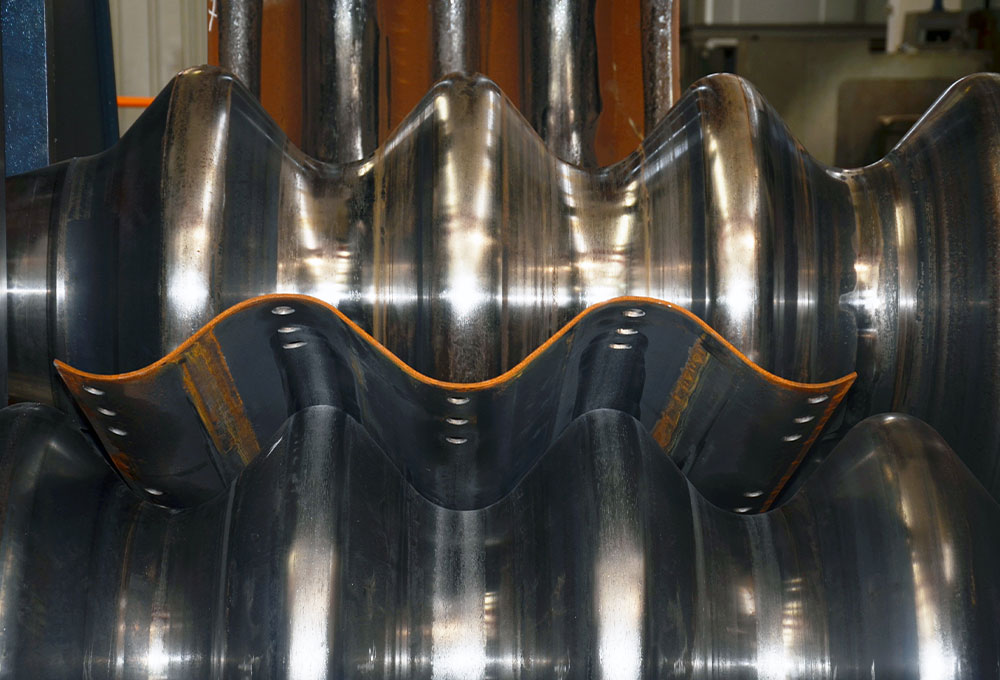

The corrugated sheet Plate Bending Machine is designed for NC controlled bending of SUPER-CORE sheet metal or any type of corrugated sheet or guard rail. A variable geometry 3 rolls or 4 rolls Plate Bending Machine, designed to also bend structural corrugated sheets for concrete bridges. reinforced, up to 300 mm high and 15 mm thick.

Advantages

Advantages

Standard equipment

- Variable geometry machine

- Electronically driven machine – integral hydraulic

- All rollers rotate on double row spherical radial bearings

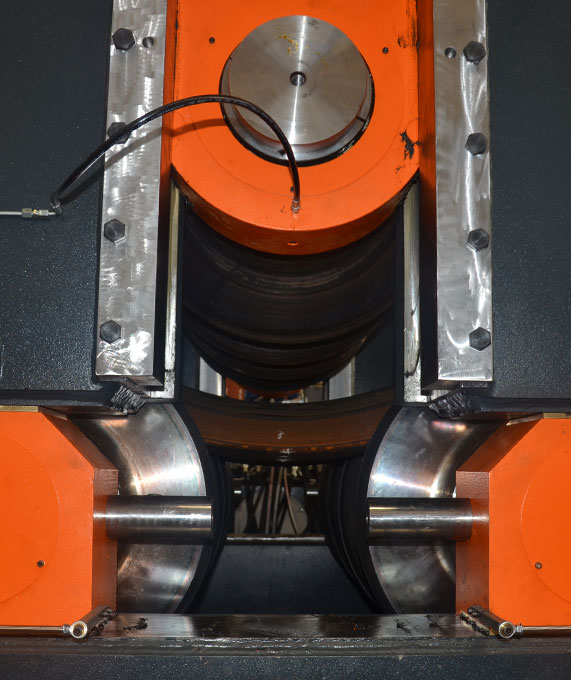

- Three rollers with independent positioning movement through hydraulic cylinders

- Forged, quenched and tempered rollers

- Motorized upper roller with planetary reduction gear + hydraulic motor

- N ° 2 rotation speeds, selectable from the control panel

- Side rolls with automatic braking system to prevent sheet slippage

- Quick system for changing the upper roll

- Electronic control of the parallelism of the rollers (with automatic adjustment controlled by SIEMENS PLC) for a perfect balance

- Electronic inclination of the upper roller and side rollers, controlled directly by the Siemens Touch Panel

- The machine is set up with a SIEMENS KTP1200 PN type Touch Panel operating panel with 12 ″ color Touch Screen display machine alarm

- Hydraulic unit consisting of: motor pump unit, solenoid valves, maximum pressure valves to protect the system from overload, located in a single manifold block to prevent oil and pressure leaks

- Heat exchanger to keep the hydraulic oil at the most appropriate temperature

- Hydraulic components Bosch-Rexroth, Vickers or equivalent

- Hydraulic opening bracket to allow the extraction of the tube in a horizontal position

- Automatic centralized lubrication with preselectable cycle from the touch panel

- All the controls are placed on an independent control console

- Low voltage at the controls, 24V DC

- Siemens electrical components or equivalent

- Air cooling system for oil

- Visualization of alarms and diagnostics on the display to signal all operating anomalies

- Machine certified according to “CE” regulations

- Safety devices for an immediate stop of machine movements consisting of mushroom-shaped emergencies and machine block perimeter cable

- Standard working temperature: (+ 15 °, + 35 °)

- Instruction manual in the language of the country of destination, complete with hydraulic and electrical diagrams, drawings of the foundations and all the equipment necessary for the installation of the machine

Equipment

Gallery

WE HAVE THE SOLUTION RIGHT FOR YOU