Vertical Plate rolling Machine

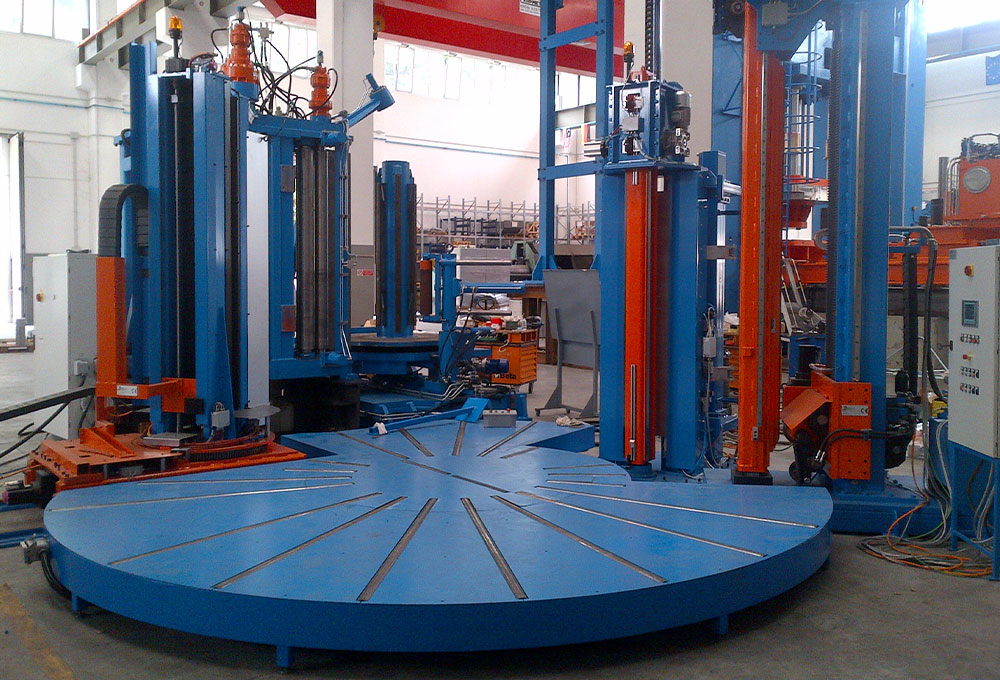

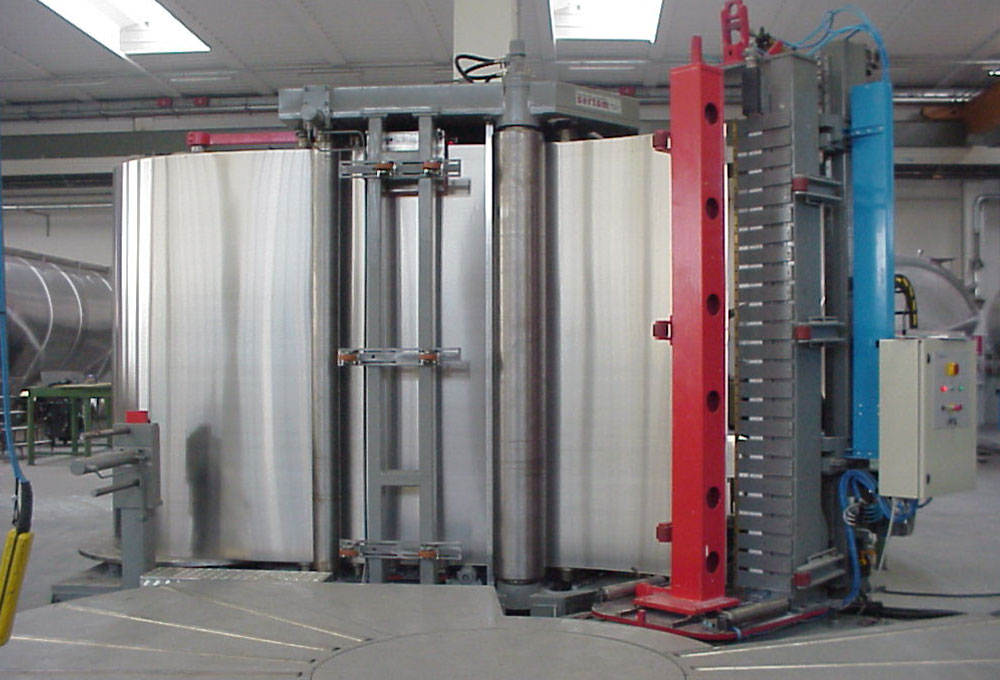

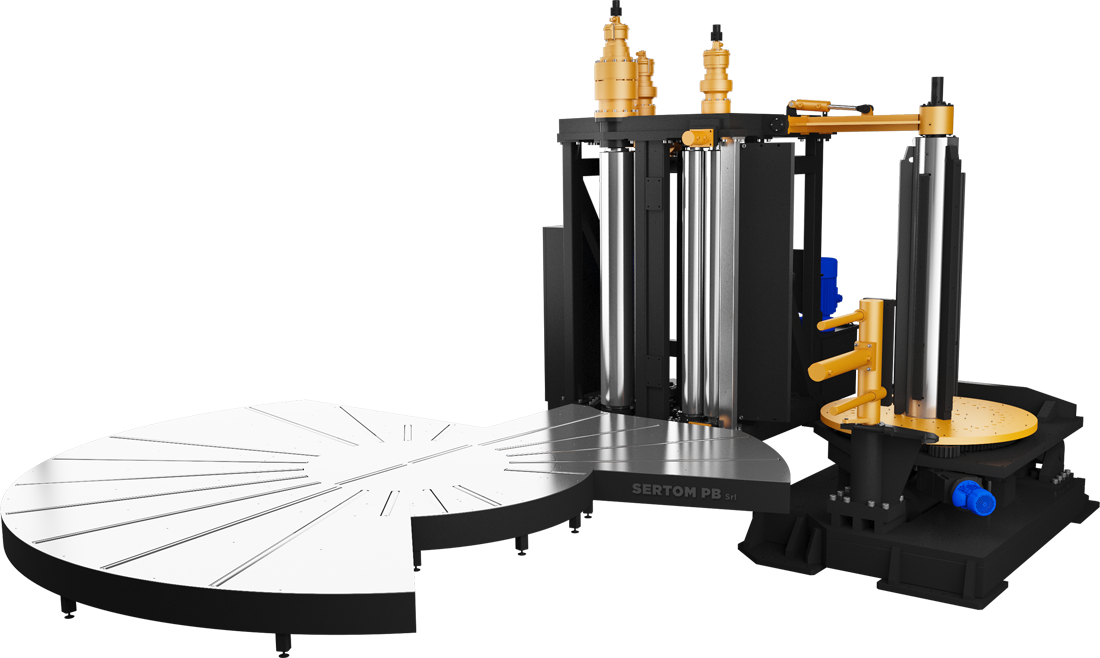

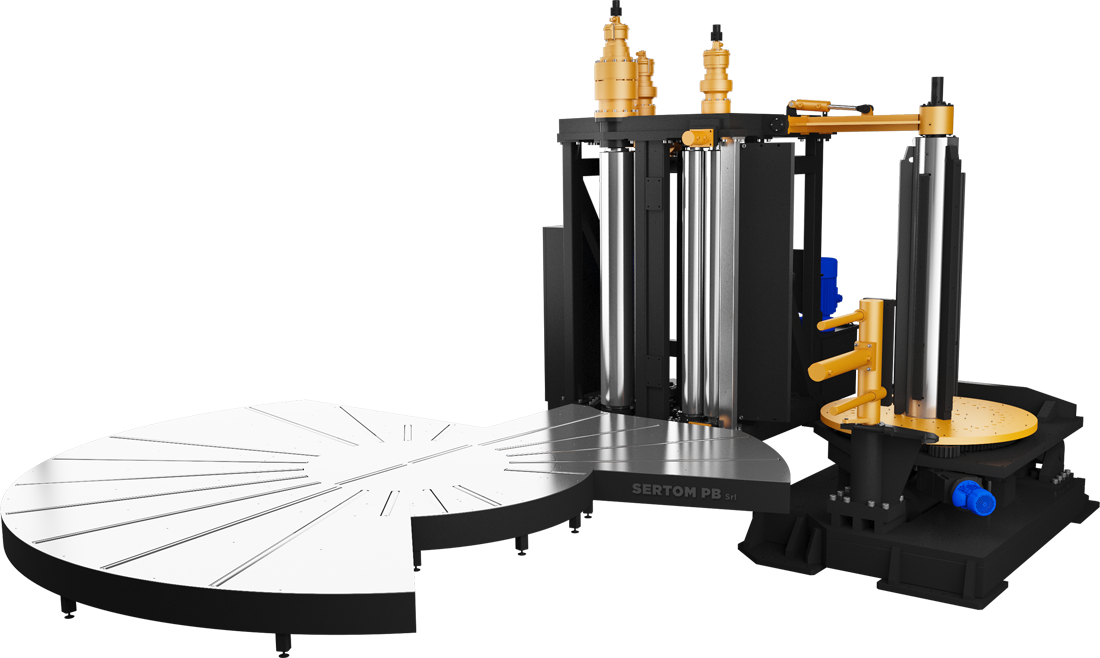

A special vertical plant for unwinding sheet metal from coils and bending medium-large diameters.

A machine designed for the production of silos starting from a coils, customizable with the cutting and welding system. It is not a simple vertical Plate Bending Machine, but a much more complete machine. It is in fact made with a coils feeding system ( motorized), with the pre-bending rolls (to eliminate the spring back return of the coils) and the asymmetrical plate roll to obtain the desired diameter. Furthermore, the rolls must to lead the sheet metal to the pinch rolls in the ideal position for the bending, even when the coils are almost exhausted.To make this possible, one of the rolls is mobile and at the output the sheet is supported by a horizontal orientable roller.

Advantages

Advantages

Standard equipment

- Coils holder platform with hydraulic motor for coils rotation

- Series of vertical infeed rolls (mobile and fixed) for flattening and elimination of sheet tensions while unwinding the coils

- Integral hydraulic drive machine

- All rollers rotate on two-row spherical radial bearings of the best brands

- Two rollers with independent hydraulic positioning movement

- Electronic control of parallelism on the pinch roller and on the folding roller

- Variable rotation speeds, with selector from the control panel

- NC a for the control of the sheet development and the control of the bending radius

- Electronic-hydraulic control of the position and parallelism of the folding roller and of the parallelism of the central roller (stapler), via NC

- Special carbon steel rolls, subjected to heat treatment and induction hardening treatment

- Hydraulic unit consisting of: motor pump unit, solenoid valves, maximum pressure valves to protect the system from overload

- Heat exchanger to keep the hydraulic oil at the most appropriate temperature

- Rexroth hydraulic components or equivalent

- Hydraulic motor coupled to a planetary gearbox, directly mounted on the upper roller

- Siemens electrical components or equivalent

- Centralized grease lubrication with preselectable cycle

- All the controls are placed on the mobile control console

- Low voltage at the controls

- Visualization of alarms and diagnostics on the NC display to signal all operating anomalies

- Safety devices consisting of mushroom-shaped emergencies and machine blocking perimeter cable

- Machine certified according to “CE” regulations

- User manual in Italian, complete with electrical and hydraulic diagrams

Equipment

Application sectors

Sectors

Gallery

WE HAVE THE SOLUTION RIGHT FOR YOU