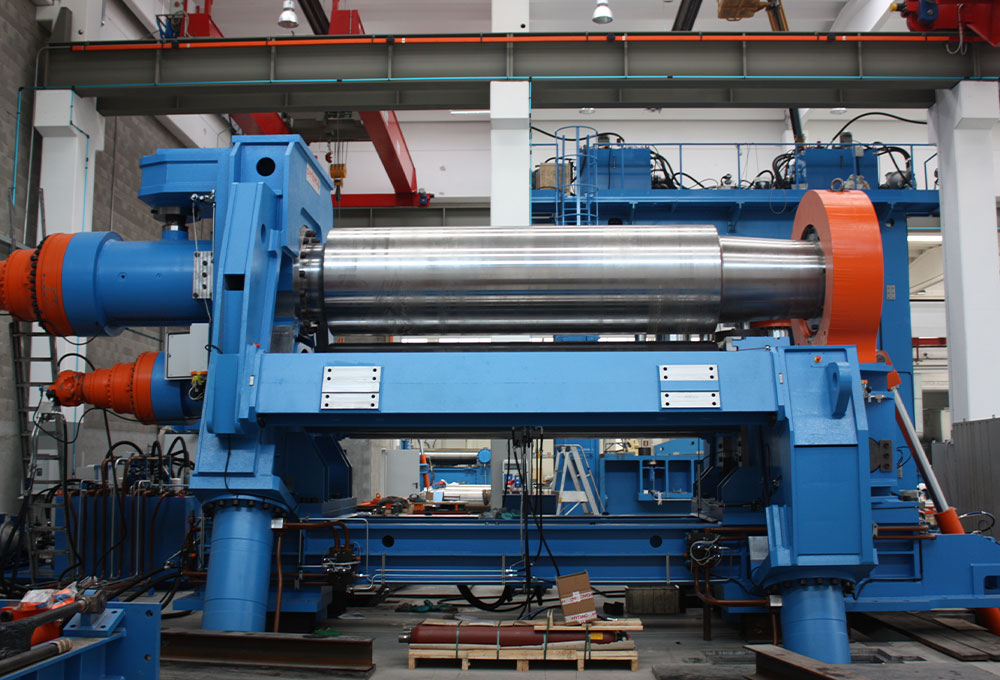

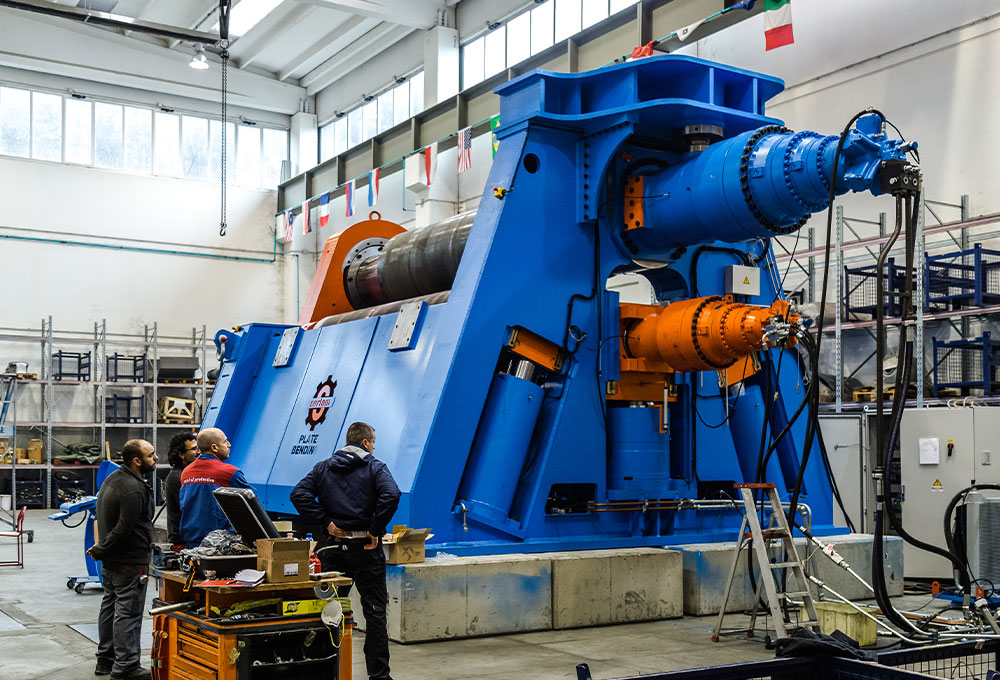

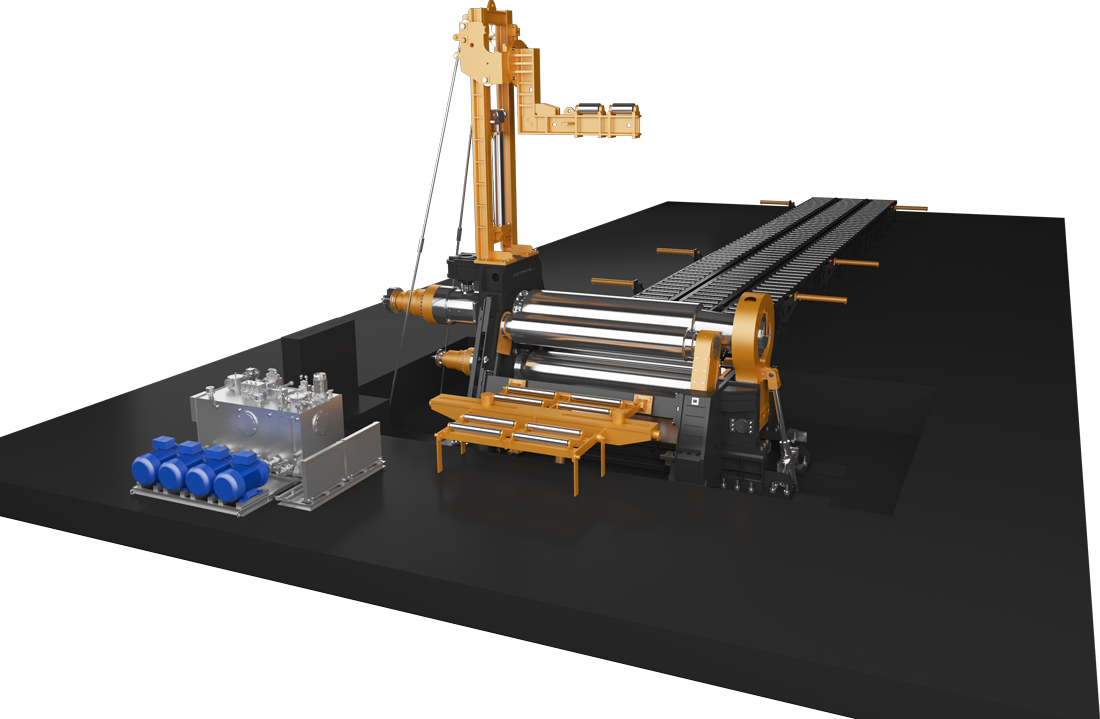

4 rolls plate bending machine

Dea 4R

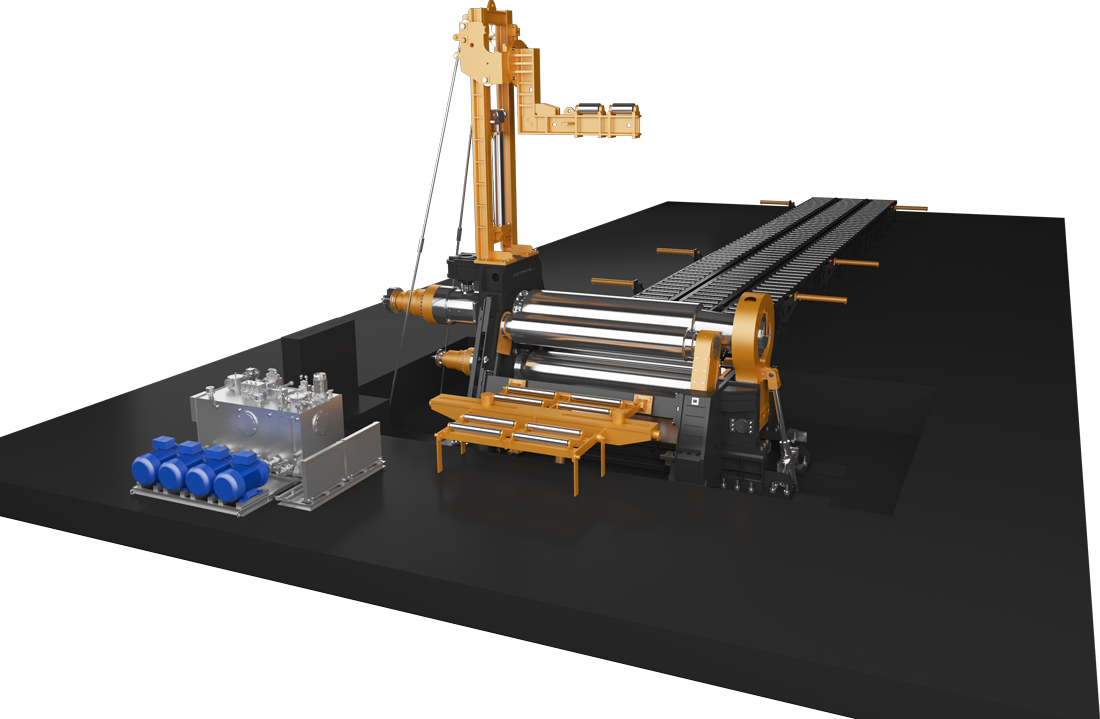

The DEA 4R hydraulic Plate Bending Machine is an extremely robust machine, characterized by the movement of the side rollers on straight guides.

Thanks to its structure and the high precision of the movements given by the technologically updated electronics, accuracy is ensured in the invitation and bending phases. All the operations of the machine are controlled by a state-of-the-art PLC and upon request it is An easy-to-use CNC control is also available. The ideal machine for mass production.

Advantages

Advantages

Standard equipment

- Integral hydraulic drive machine

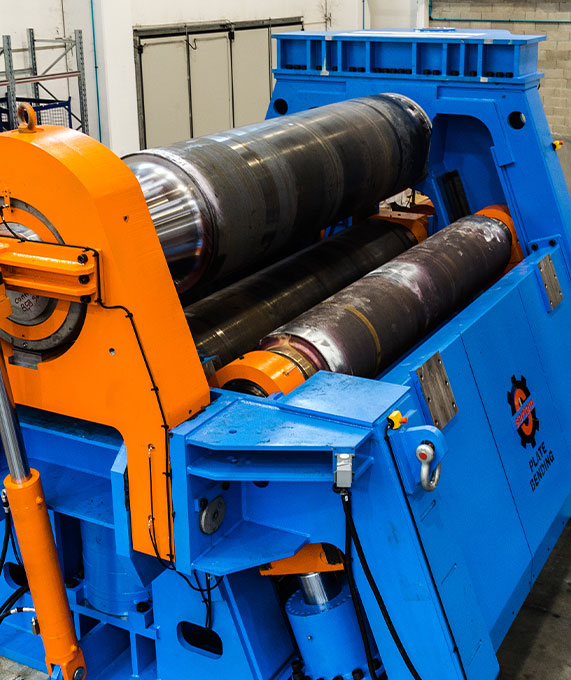

- All rolls rotate on double row spherical radial bearings

- 2 motorized rolls with n ° 2 planetary reducers + n ° 2 hydraulic motors for the rotation of the rolls

- System of rectilinear guides for the translation of the lateral and lower rolls

- Lateral and lower rolls with independent positioning movement through hydraulic cylinders

- Rolls in special carbon steel (42Crmo4), subjected toquenching and tempering treatment

- Electronic inclination of the side rolls for the production of conical sheets, controlled directly from the control panel

- 3 preselectable rotation speeds with selector from the control panel

- Electronic control of the parallelism of the rolls (with automatic adjustment controlled by SIEMENS PLC) for a perfect balance and a guaranteed tolerance of 0.1 mm

- Touch Panel SIEMENS KTP 1200 PN type operating panel, with 12 “color display By changing the screen, it is possible to view on the display: the position of the rolls, the inclination of the rolls, diagnostics and alarms of the machine functions

- System to control and use PLC via Internet, for software changes and machine anomalies solutions directly from our headquarters

- Automatic speed / pressure compensation between the upper and lower rolls

- Hydraulic unit consisting of: motor pump unit, solenoid valves, maximum pressure valves to protect the system from overload Heat exchanger for hydraulic oil

- Bosch-Rexroth hydraulic components

- Hydraulic opening bracket to allow horizontal extraction of the product tube

- Centralized lubrication with preselectable cycle

- All the controls are placed on an independent control console

- Siemens electrical components

- Visualization of the alarms on the display to show all the anomalies in progress

- Electric motor to drive the hydraulic pump

- SICK optoelectronic protective devices for immediate stopping of machine movements

- Machine certified according to “CE” or “UL” or “CSA”

- Instruction manual in the language of the country of destination, complete with hydraulic and electrical diagrams, drawings of the foundations and all the equipment necessary for the installation of the machine

Equipment

Application sectors

Aerospace industry

Carpentry and mechanical workshops

Energy industry

Ground handling

Heating, ventilation, pumps, burners and filters

Metal structures

Offshore structures and oil platforms

Pressure tanks and heat exchangers

Production of pipes

Shipbuilding

Tanks and silos

Truck and train tankers

Wind Tower

Sectors

Gallery

WE HAVE THE SOLUTION RIGHT FOR YOU