STRAIGHT END OR FLAT END.WHY IS SO IMPORTANT FOR THE DETERMINATION OF THE PERFORMANCE OF A ROLLING MACHINE?

The correct definition of straight end is the follow: the straight end is the edge that remain straight ( or not curved to size ) on both the end of the plate.

Is impossible obtain a straight end equal to zero, because for the geometric configuration and the way of operating of the rolling machines it would require an infinite high force.

The flat end result to be the one of the most important parameters for choosing a rolling machine, infact the smaller is it, the greater the force required by the rolling machine, the diameter of the roller and essentially, the size of a rolling machine.

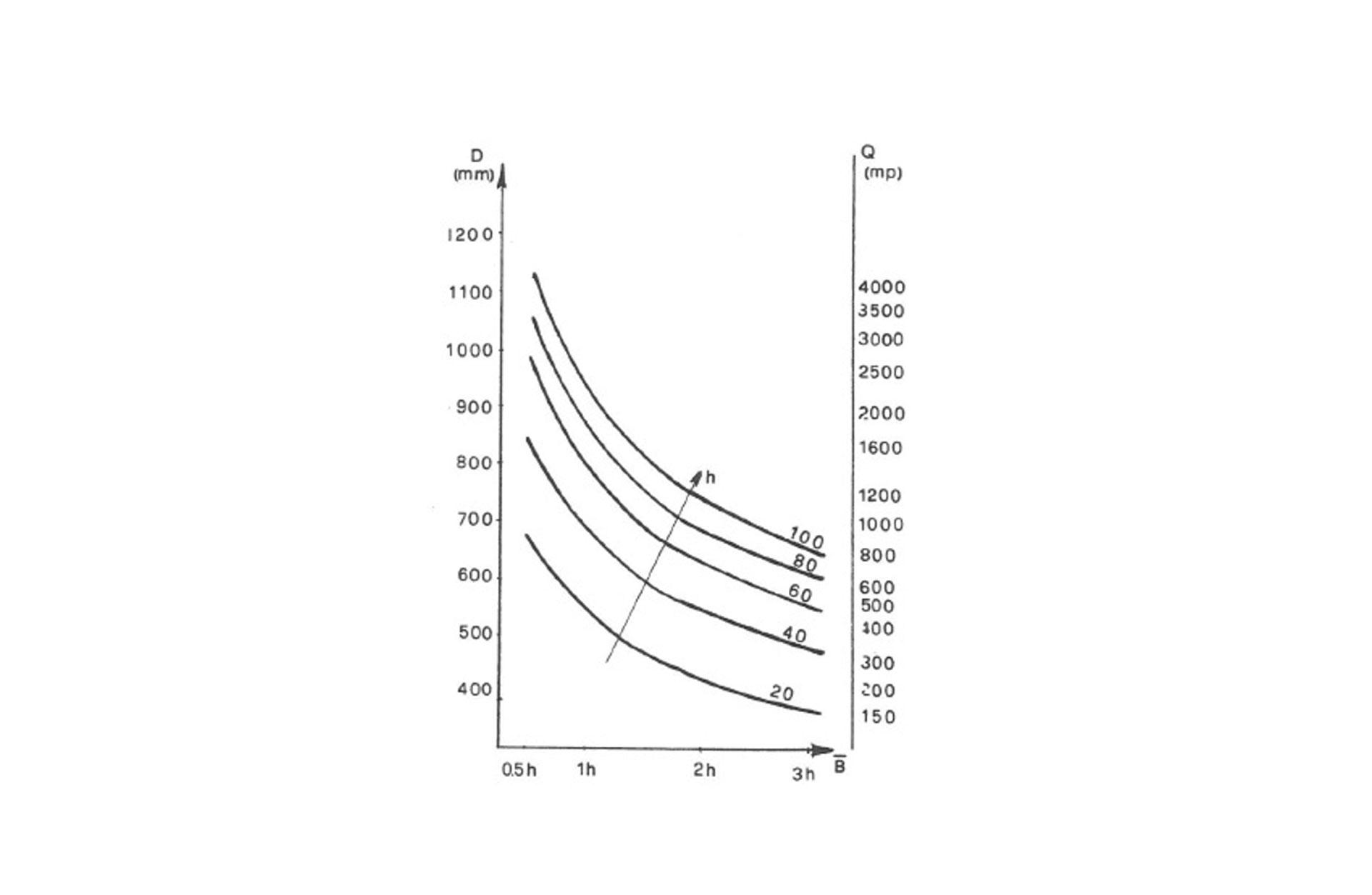

D= diameter of the top roll

h= thickness

B= straight end

Q= force

The measurement of the straight end can be indicate in two ways, identical in substance, but formally different:

- As a percentage of the sheet tickness:B= γ * hWhere the γ factor is usually included between 0.8 and 5, and it depends on the application needs of the rolled plate.

- As “absolute Value”, so the real measure of flat end in the country’s unit of measurement.